Advantages of Antistatic Coating

- Stable resistivity in extreme temperature conditions

- Smooth, uniform surface with strong adhesion

- Precise dimensional control

- Suitable for both new and refurbished parts

- Custom development capabilities

- Reliable process control for complex applications

- Consistent accuracy in reworked components

Electrostatic Dissipative Coating Specifications

- Surface Resistivity: 106~108Ω

- Coating Thickness: 40~60µm

- Triboelectric ChargeGeneration: < 20 V/inch

- Manufacturing Tolerance: 15µm

Applicable Environments & Industries

- For antistatic (customizable resistivity), insulation, non-stick, wear, temperature, and chemical resistance needs

- Used in optoelectronics, semiconductor packaging, and testing industries

- Supports AI computing and 5G high-end manufacturing

- Custom colors for AOI inspection and recognition systems

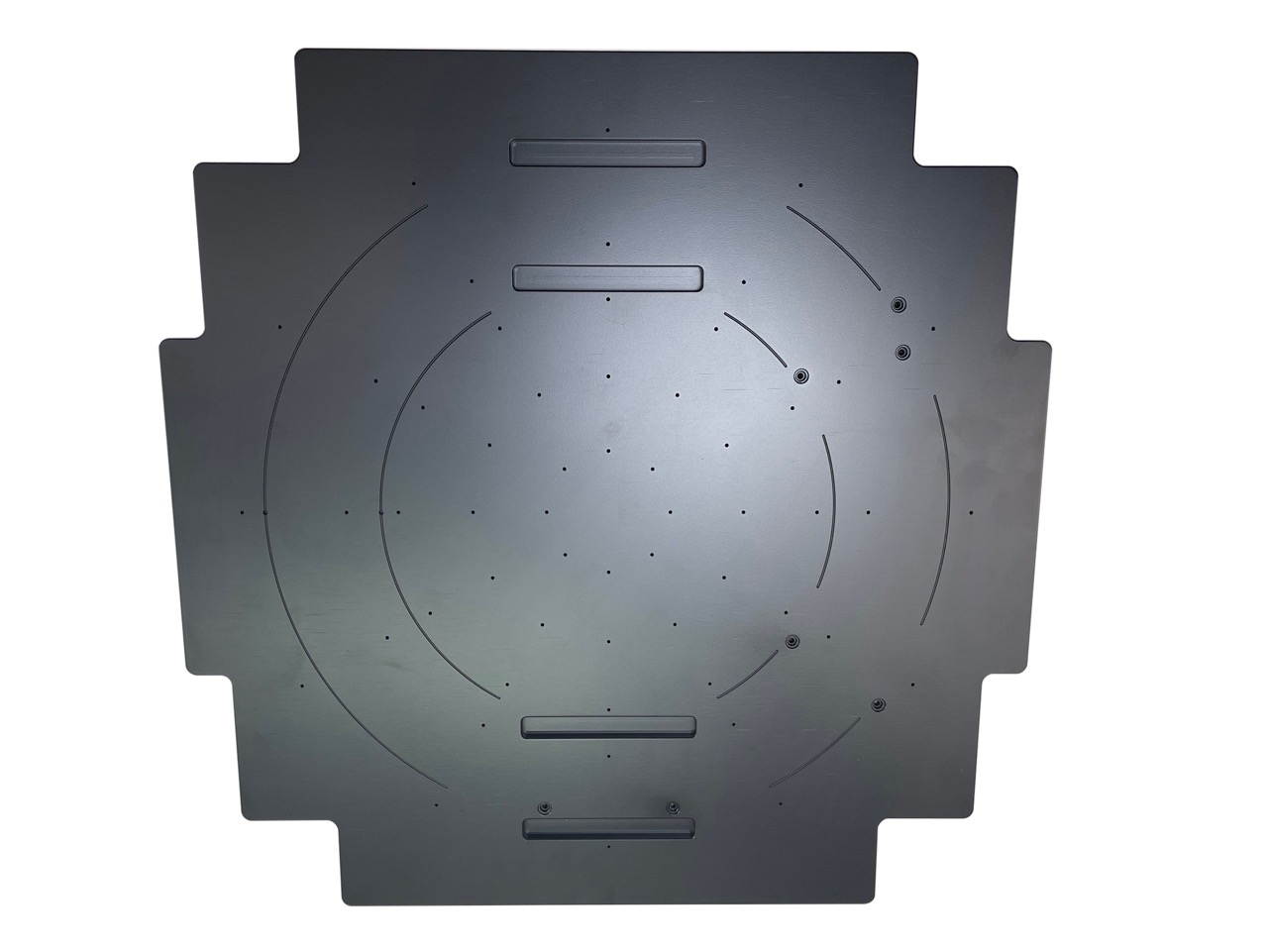

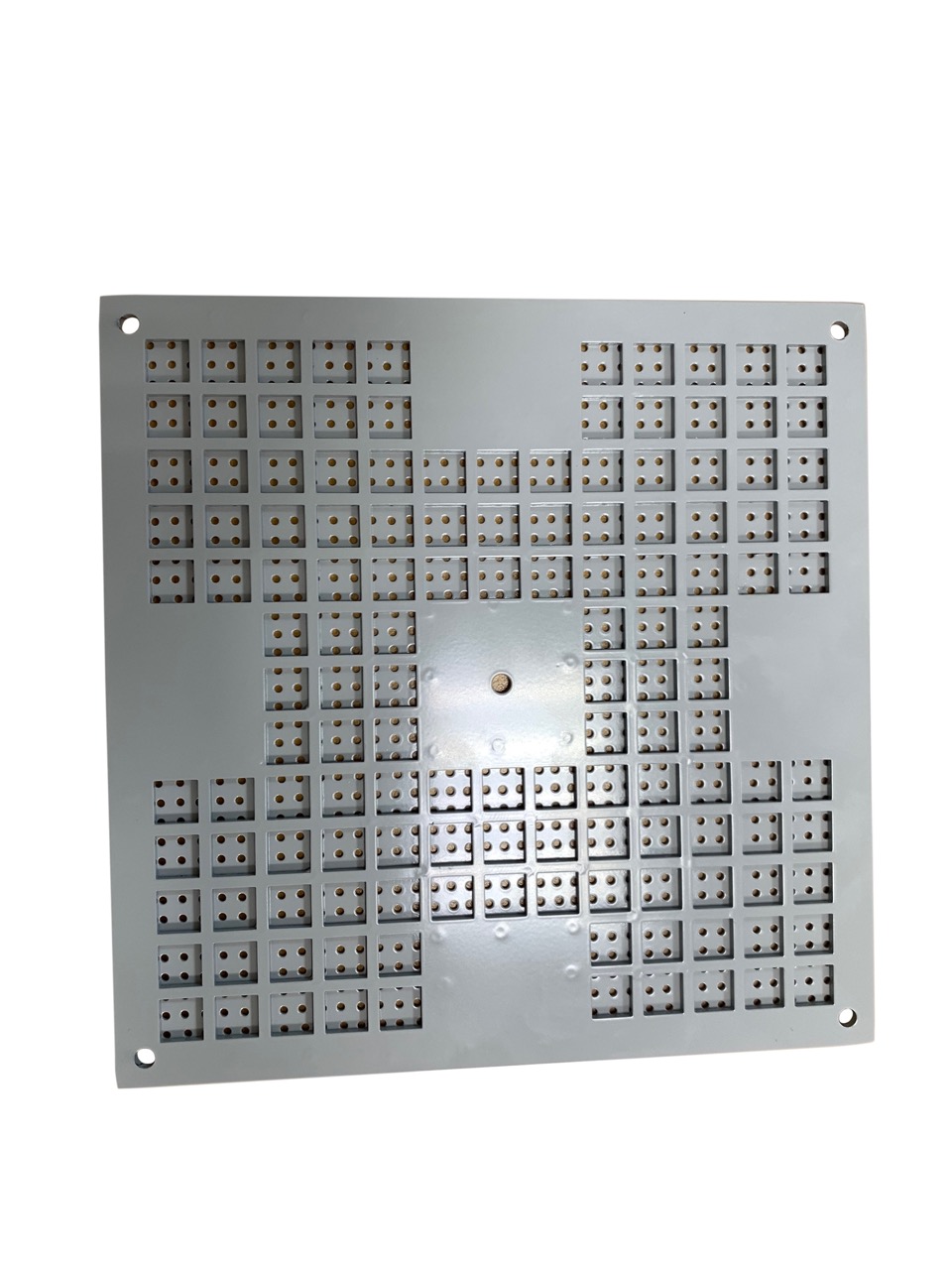

- Applied to vacuum chucks, robotic arms, and precision equipment

- Suitable for machine fixtures: hot plates, trays, IC contacts, nozzles, clamps, and more